The Side Effect Club: UMaine Breakthrough Makes 3D-Printed Parts Stronger and Lighter “`html

Rethinking Strength: UMaine’s Breakthrough in 3D-Printed Parts

Estimated reading time: 5 minutes

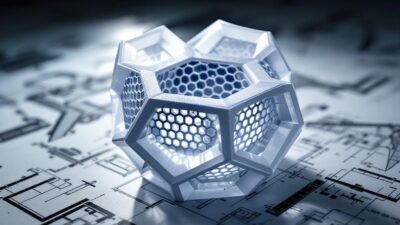

- Lightweight Innovation: UMaine engineers have developed a method for predicting the strength of lightweight 3D-printed parts.

- Industry Impact: This advancement could significantly affect the aerospace and automotive industries.

- Predictive Modeling: A new predictive model utilizes big data to enhance part strength forecast.

- Future Possibilities: The ongoing developments in 3D printing may revolutionize transportation.

Table of Contents

- Light as a feather, Strong as Steel

- Tech Diving: The How Behind the Hype

- Airplanes Fly Lighter, Cars Drive Faster

- Engineering Revolution: A Step UMaine, Not A Leap Behind

- Closing Ruminations: Our Tech Tomorrow?

- FAQ

Light as a feather, Strong as Steel

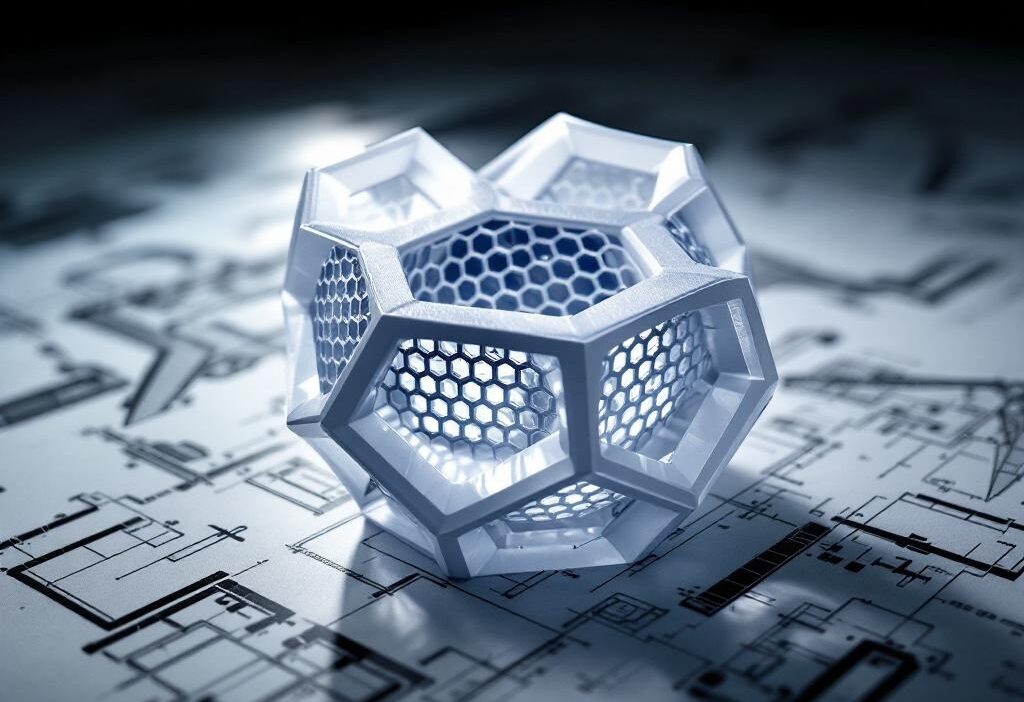

Engineers from the University of Maine are flexing their muscles in the world of 3D printing. If you’re still thinking of 3D prints as delicate, brittle figurines or mock-ups, it’s time to update your tech lexicon. The world of 3D printing has moved lightyears ahead, with UMaine engineers finding a method of predicting the strength of lightweight 3D-printed parts. Industries like aerospace and automotive could soon wave goodbye to their heavyweight woes, thanks to this innovative development.

Tech Diving: The How Behind the Hype

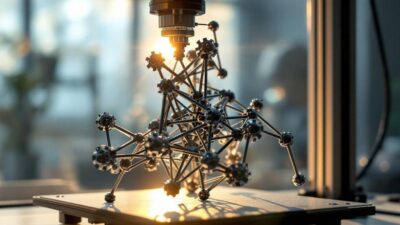

So how did they do it? It might bring to mind complex tools like n8n, LangChain, or Pinecone. But in reality, it’s a bit simpler to understand. The engineers deployed a new predictive model using good old big data. By aggregating data from multiple tests of 3D-printed parts, they have been able to predict the strength of these lightweight components. No doomsday prophecy, just cold, hard science.

Airplanes Fly Lighter, Cars Drive Faster

Think about it. This isn’t just about creating dainty drones or arty car models. The ripple effect on the aerospace and automotive industries is considerable. These industries are constantly on the hunt for ways to shave off a gram from their machines without compromising performance or safety. The UMaine development could, potentially, be their golden ticket to achieve that.

Engineering Revolution: A Step UMaine, Not A Leap Behind

Don’t get me wrong. We’re not quite at a “Fly me to the moon in a 3D-printed rocket” scenario yet. But who knows? With this advance, we’re certainly a step UMaine – and that’s saying something. Go ahead and keep your eyes peeled for the next big announcement because, at this rate, it won’t be far behind.

Closing Ruminations: Our Tech Tomorrow?

Is this the way of the future? Will our aircrafts become feather-light and cars seem sprint-speed, all thanks to 3D printing? While we don’t hold a crystal ball, this UMaine development certainly puts a strong argument forward. What do you think? Could your next Martian Rover or family car be partly 3D printed? Ponder on that, fellow AI and tech aficionados. Until next time.

FAQ

Q: What is the main discovery by UMaine engineers?

A: They developed a predictive model for the strength of lightweight 3D-printed parts.

Q: How could this discovery impact industries?

A: It has the potential to significantly affect aerospace and automotive industries by promoting lighter, stronger components.

Q: Are we near a future with 3D-printed vehicles?

A: While significant advancements are made, we’re still in early stages of development.