The Side Effect Club: UMaine’s Breakthrough Makes 3D-Printed Parts Stronger & Lighter “`html

Conquering the 3D Space: UMaine Engineers Unveil a Gamechanger in 3D-Printed Parts

Estimated Reading Time: 5 minutes

- UMaine engineers have developed a method for stronger, lighter 3D-printed parts.

- The gyroid structure enhances strength without adding weight, benefiting multiple industries.

- Applications in aerospace, automotive, and medical device manufacturing signify major advancements.

- UMaine’s breakthrough is poised to change the landscape of 3D printing technology.

Table of Contents

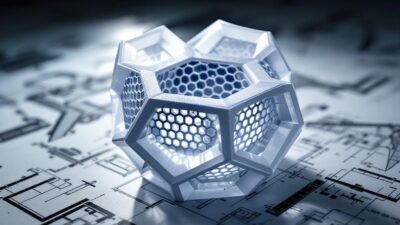

Like Reinventing the Gyroid

Do you remember when 3D-printing was just a visionary concept? When it was only showcased in sci-fi films and rarely mentioned in professional meetings? Now, it’s not uncommon to have a 3D printer humming its way in your coworker’s cubicle. Enter UMaine engineers. They’re not just participating in the 3D-printing revolution. They’re changing the game with a new method to produce stronger, lighter parts.

Using a blend of computer modeling and old-fashioned physical experiments, the UMaine teams have figured out how to optimize the gyroid. Nope, not the quarantine-induced hair phenomenon. We’re talking about an intricate infill structure used in 3D printing.

The gyroid is an infinitely continuous, minimal surface that has a triply periodic structure. If you’re wondering what the heck that means – consider it as the special sauce that adds strength without heaviness to applications in aerospace, automotive, and medical device manufacturing.

Tools such as LangChain could be employed to transcribe and translate these tech-heavy terms into plain English for ease of understanding across multiple demographics. And as with Pinecone, we could search for similar research or phenomena using its similarity search capability.

Lighter. Stronger. Better.

You might be asking why this matters. Well, think of the potential here. We’re talking about aerospace parts that can withstand harsh space conditions yet light enough to significantly reduce launch costs. The dreamy sports car that’s not just about swift wind, but also about exemplary safety. Not to mention medical devices that are durable yet lightweight to ease the burden on patients. Feels like some sort of modern alchemy, isn’t it?

And Now, for the Best Part…Well, Parts.

3D printed parts, to be precise. An art and science previously beset with the challenge of balancing strength versus weight. UMaine’s breakthrough is remaking the rules of the tech game. Other teams are already taking notes, and you should too. If you’re working with automation systems like n8n, imagine the possibilities when incorporating these stronger, lighter, 3D-printed parts.

4-page research briefing or these bite-sized bullet points. You still got the point.

FAQ

- What is the gyroid structure?

The gyroid is a minimal surface structure that optimizes strength and weight in 3D printing. - What industries can benefit from UMaine’s 3D printing advancements?

Industries include aerospace, automotive, and medical device manufacturing. - How could these advancements impact manufacturing costs?

Stronger and lighter parts can significantly reduce costs, especially in aerospace applications.